Our services

Our company offers a range of targeted services to fully meet the needs of our customers. In addition to providing the items available in our catalog, we place great emphasis on direct collaboration, working closely with our customers to fully understand their needs and desires. This allows us to create customized products upon specific request, ensuring tailor-made solutions that reflect the expectations and individual needs of each customer. Furthermore, we provide consultation at every stage of the project development, from choosing composite materials to product delivery, in order to fully meet customer needs. Our company is committed to ensuring the highest quality and confidentiality in all the services we offer.

DEPARTMENTS

Engineering Department

Our technical team, composed of experts in transforming ideas into detailed sketches, collaborates precisely on projects. This synergy between creativity in design and precision in engineering translates clients' visions into high-quality solutions. We use CAD and CAM to optimize the process. Once the project is defined, we proceed with industrialization, ensuring a smooth transition from concept to production.

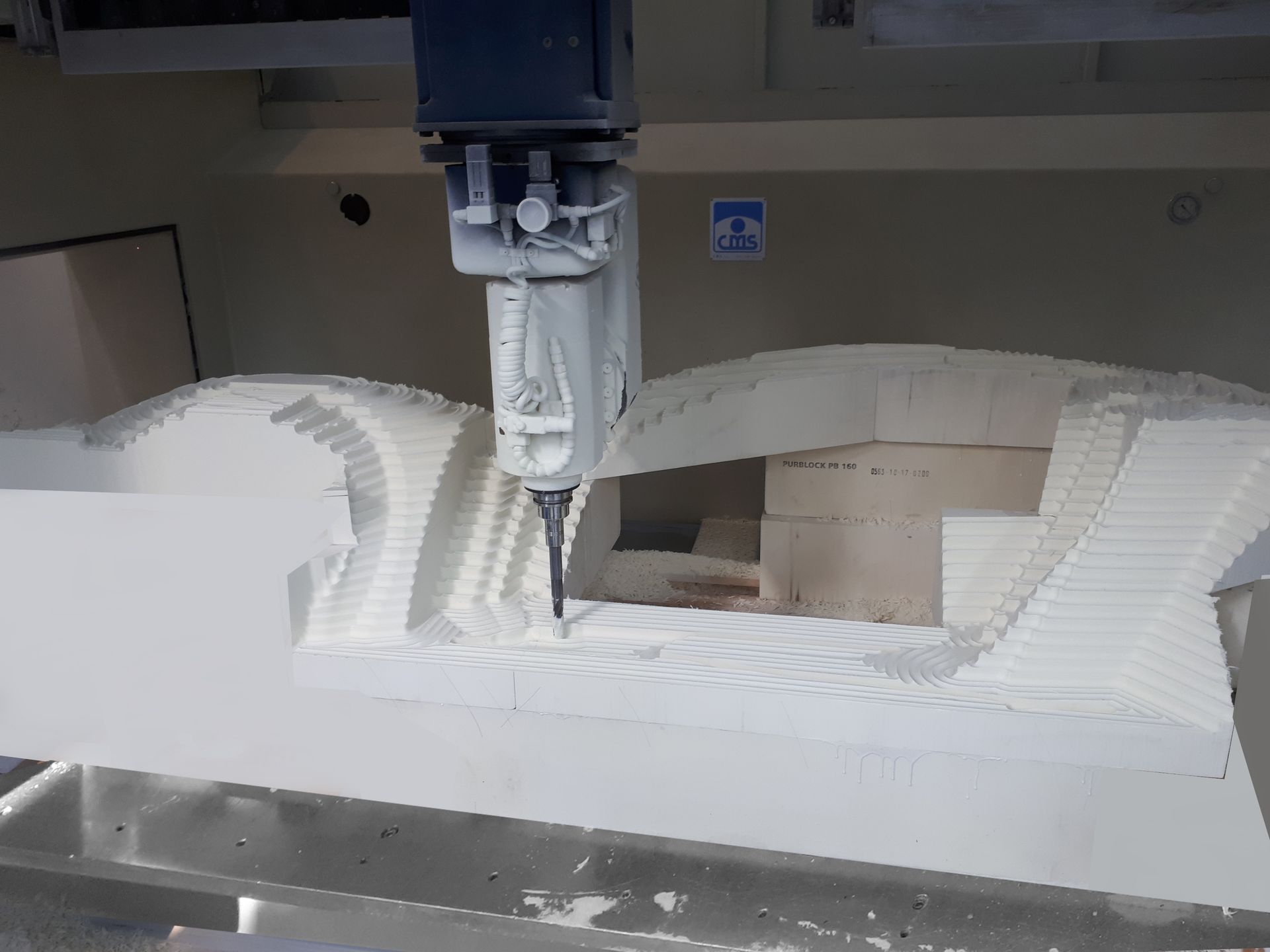

Modeling Department

We produce scaled-down or 1:1 scale models to evaluate feasibility and style with the client. We then move on to creating molds and/or equipment for prototype construction, developing matrices capable of producing a few or more complex units as needed. Sophisticated tactile or optical control systems monitor dimensions and parameters at every stage of prototype construction.

Composite Manufacturing Department

Our composites department extends into a facility entirely dedicated to this specialization. Within it, technology merges with innovation: we have autoclaves for heat treatments, cleanrooms for processing in a controlled environment, advanced vacuum preparation systems, and state-of-the-art ovens. The mold preparation phase is meticulously handled, supported by precision cutting plotters and refrigerated cells for material storage. Every product undergoes rigorous quality control, ensuring high standards. Concluding the cycle, the warehouse ensures optimal management of finished products.

Assembly Department

During the assembly phase, distributed across 8 dedicated stations, our qualified personnel meticulously attend to the alignment of components. Each station is equipped to ensure the perfect arrangement and connection of various parts. This organization, coupled with the team's expertise, guarantees that each element fits seamlessly with the others, resulting in a final product of high quality and precision.

Painting Department

Before the painting phase, each component undergoes meticulous preparation, including the application of specific primers and high-resistance paints. Subsequently, the surface is carefully processed through sanding and polishing, creating a finishing result that highlights the exceptional quality of the product. Every stage is closely supervised by experts to ensure maximum precision and perfection.

Finishing and Quality Control Department

During the finishing phase, we optimize the appearance of the components, carefully attending to every detail and enhancing the intrinsic quality of the material. Every stage is monitored by experts who ensure precision and perfection. Subsequently, the final piece undergoes rigorous quality controls, subjected to stringent procedures, to ensure that it meets our high standards and fully satisfies our customers' expectations.